Student design may lead to heart treatment for small dogs

By the time they are 10 years old, many small dogs will develop mitral valve disease, a deadly condition where a heart valve leaks. So far, the only curative treatment is a surgery that costs approximately $30,000, with only a couple teams of veterinary surgeons able to perform it with a high success rate.

Dr. Romain Pariaut, associate professor of cardiology at Cornell’s College of Veterinary Medicine, is collaborating with a team of biomedical engineering students in the Master of Engineering Program (M.Eng.) to find a cheap, less invasive and effective solution.

“The problem was trying to find a more affordable solution that could be done in a normal veterinary practice by a cardiology specialist or surgeon,” Pariaut said.

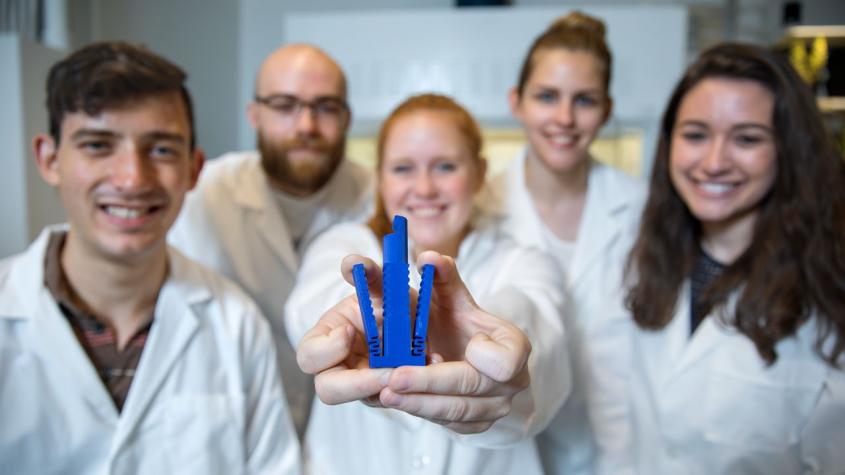

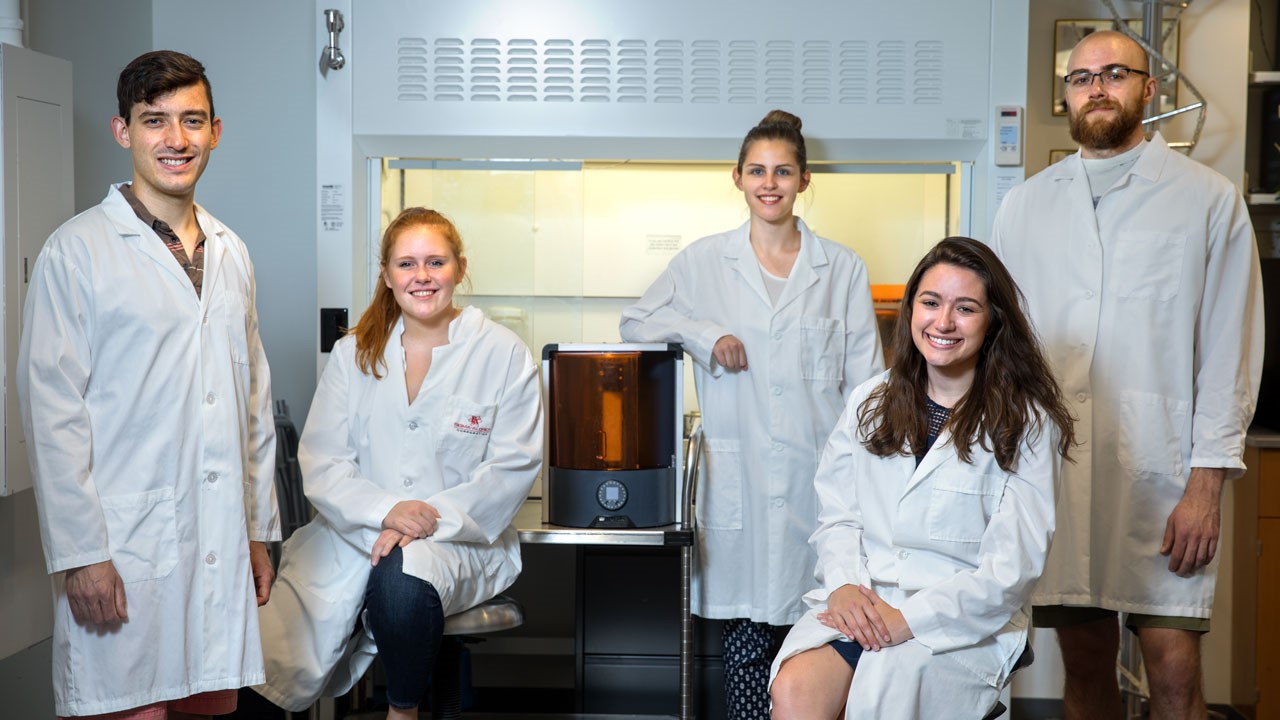

The team started the project in fall 2017 and developed a prototype: a 3 millimeter clip with the potential to repair the valve at a fraction of the cost. The clip mimics a similar but larger clip used in humans. With four of the five students having graduated in May, one of the students is continuing this year and is building a new team to further test and improve on last year’s progress.

Students lay the groundwork

The two-semester M. Eng program is a professional degree designed to fast-track students to become applied engineers or engineering managers, as opposed to research scientists.

The program includes science and engineering and professional development coursework, and instead of a standard thesis found in traditional master’s programs, the M.Eng. program requires a hands-on, real-world project design sponsored by an industry partner or a clinical organization, including the College of Veterinary Medicine and Weill Cornell Medicine.

“The sponsor has to understand that we’re not a build-to-print engineering firm,” said Dr. Newton de Faria, director of the Master of Engineering Program at the Meinig School of Biomedical Engineering. “We’re not here just to build a product.”

The end phase for each student team is to create a functional proof-of-principle prototype. If a project reaches that stage, a sponsor may negotiate intellectual property rights with students, and then use the prototype as a basis to undergo a more stringent engineering process and make it a deployable health care technology. Up to 15 percent of projects end up on shelves as viable products, de Faria added.

“We are interested in a challenging problem and the process, the byproduct is part of it,” de Faria said. “This is an educational process for the students. We deliver value, but we are not committed, just like a company that has been hired. It’s a relationship.”

Design projects undergo a series of steps, starting with students researching and verifying the need for a device or engineering solution. In the case of the mitral valve, the student team met with Pariaut, learned about the disease and observed veterinarians meeting with patients and several procedures in Cornell’s Companion Animal Hospital.

“When they were more familiar with the disease, the next step was to come up with as many ideas as they could,” Pariaut said. The team narrowed their ideas down to three of the most promising solutions, before deciding to develop a clip. “That was logical because we know that’s what’s been working in humans,” Pariaut said of the clips that are inserted through a large blood vessel. The clip looks like a staple and works by clipping together two valve flaps where the leak is largest.

Meeting challenges

“Scaling it down to fit inside a [small] dog was the greatest challenge,” said student team member Samuel Tome '17, M.Eng. ’18. Other team members included Erin McConnaghy, Alexandra Meilhac and Michael Rose, who all graduated with their M.Eng. in May, and current M.Eng. student Lindsay Hale '18.

“We had to become really creative with our manufacturing techniques since we are designing things on a scale of a couple of millimeters max,” Tome said.

Other challenges included selecting a material that would have the right mechanical properties and that would be biologically and blood compatible. A titanium alloy proved to be the most promising choice. They also needed to understand the clamping force required to hold a dog heart valve closed, a difficult task when working with models. Along with designing a solution, the team also plotted ways to test the clip and refine it for future generations of the device, Tome said.

The new team will focus on building a cardiac biosimulator that will allow them to test prototypes of devices to optimize them, with the ultimate goal of trying the clip in a living dog.

“The main thing I gained [from the project] was really examining a medical problem and designing a solution around that problem using all the different skills available to me,” Tome said. “Our advisers left it up to us to design something from the ground up.”

By Krishna Ramanujan